Packaging Structure: A Comprehensive Guide

For any business that produces packaged products, packaging structure is an important part of the production process. But what exactly is packaging structure? In simple terms, it is a template for designing a custom box or packaging and plays a key role in the production process. Let’s take a closer look at the principles of cutting lines and how they work.

Baly Agency

Titles

What is Packaging Structure?

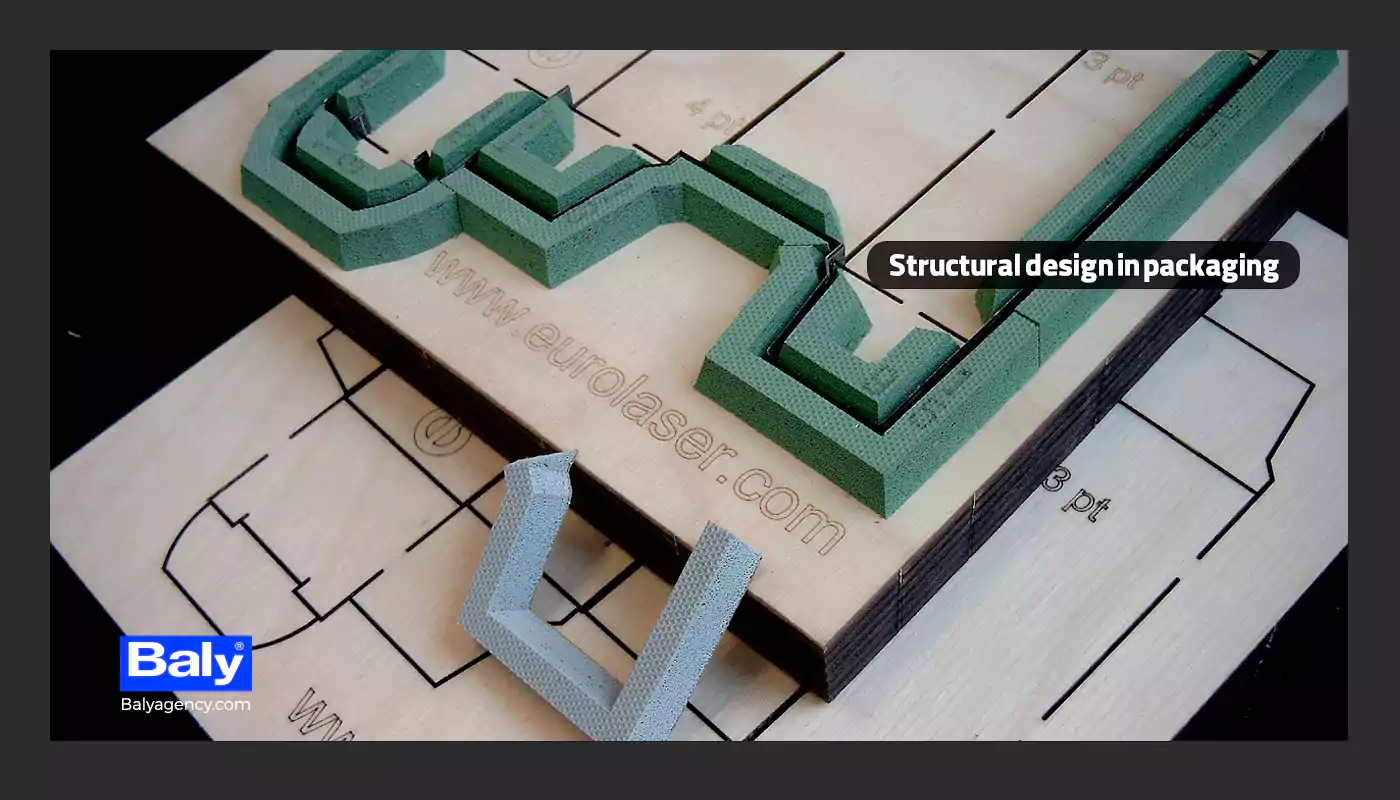

What is the Difference Between Packaging Structure and Packaging Die?

• Packaging Structure: A digital file created in design and engineering software that shows all dimensions, cutting lines, and other details.

• Packaging Die: A physical tool made based on the packaging structure. This die has cutting blades and is mounted on a wooden board that cuts or folds the cardboard exactly according to the structure design.

How Do Packaging Structure and Die Work?

How to Design a Packaging Structure?

Creating an appropriate structure requires knowledge in box making and graphic design software such as Illustrator and Corel. Additionally, engineering software like AutoCAD is often used in this process. With the help of these programs, designers can create complex shapes and lines that accurately represent packaging designs.

Moreover, if designers have sufficient experience in

die-making processes, they can better understand how their designs will

translate into packaging materials. Once the design is complete, they can send

it directly to printing houses for die cutting based on the provided

specifications.

Reviewing the Packaging Die Manufacturing Process

Conclusion

The packaging structure, as a two-dimensional design, outlines the roadmap for producing packaging. The packaging die is a tool used for cutting and creating fold lines on cardboard or cartons. Understanding the components of an effective cutting line is essential for packaging designers and custom carton makers.

Recent Posts

Baly Agency

The Baly Agency is a place where creativity and performance are directly connected, driving forward movement. Our areas of expertise include packaging design, brand visual identity design, website design, and the production of promotional animations.